What is Fiber Cement Board? An Engineering Perspective

In the perpetual search for structural stability and longevity, the construction industry has evolved beyond the limitations of simple timber and monolithic concrete. The modern architectural landscape demands a material that balances compressive strength with tensile flexibility, fire resistance with workability. This is the engineering definition of fiber cement board.

What is Fiber Cement Board? An Engineering Perspective

In the perpetual search for structural stability and longevity, the construction industry has evolved beyond the limitations of simple timber and monolithic concrete. The modern architectural landscape demands a material that balances compressive strength with tensile flexibility, fire resistance with workability. This is the engineering definition of fiber cement board.

Unlike traditional masonry, which can be heavy and brittle, or gypsum, which is susceptible to moisture, fiber cement is a sophisticated composite material. It represents a synthesis of three primary components: Portland cement (the binder), high-purity silica sand (the aggregate), and reinforcing fibers. When combined under precise industrial conditions, these elements transform into a calcium silicate structure that outperforms its individual components in almost every metric.

However, not all boards are created equal. The market is flooded with variations in density, curing processes, and fiber quality. This guide moves beyond surface-level marketing to analyze the technical reality of fiber reinforced cement board. We will dissect the history of the Hatschek process, the molecular impact of autoclaving, the critical importance of density, and why this material has become the global standard for heavy-duty cladding and flooring applications.

The Evolution: From Hatschek to Modern Composites

To understand the material, one must understand its origins. The technology was invented in the early 1900s by Ludwig Hatschek, who sought to create a lighter, more durable alternative to stucco. His breakthrough was the ‘Hatschek machine,’ a device that picks up thin layers of cement and fiber slurry on a rotating cylinder, laminating them together to form a sheet. This laminar structure is crucial—it functions similarly to plywood, where multiple layers provide cross-directional strength.

For decades, asbestos was the fiber of choice due to its incredible tensile strength and fire resistance. However, the discovery of its severe health risks (specifically Mesothelioma) led to a global shift in the 1980s. Modern engineering replaced asbestos with Cellulose—organic fibers derived from high-grade kraft pulp. While safer, cellulose required new chemical formulations to ensure the board wouldn’t rot.

Today, TSM utilizes advanced formulations that combine these organic fibers with mineral additives. The result is a non asbestos cement board that retains the mechanical benefits of the original invention without the toxicity. This evolution has positioned fiber cement as the premier choice for green building certifications like LEED and BREEAM.

Manufacturing Physics: The “Autoclaved” Difference

The differentiation between a low-grade board and a high-performance board begins in the curing chamber. Cheaper boards are often ‘air-cured,’ relying on natural hydration over weeks. Premium boards, like those from TSM, undergo an ‘Autoclave’ process—a high-pressure steam curing method that fundamentally alters the chemical structure.

The Tobermorite Effect

Inside the autoclave, temperatures reach 180°C under high atmospheric pressure. Under these conditions, the silica sand reacts chemically with calcium hydroxide (a byproduct of cement hydration). This reaction creates a stable crystalline structure called ‘Tobermorite.’

Tobermorite is the secret to dimensional stability. An air-cured board retains ‘moisture memory,’ meaning it may shrink or expand significantly with humidity changes, leading to cracks in the paint or finish. In contrast, an autoclaved product from a professional cement board factory is chemically inert. It has already undergone its maximum shrinkage during manufacturing. This means it will not warp, crack, or delaminate even when installed on a building facade exposed to extreme freeze-thaw cycles.

Specs Breakdown: The Logic of Density

In fiber cement specifications, density is the primary indicator of durability and application suitability. Boards are generally categorized into three tiers:

1. Low Density (< 1.0 g/cm³): Used primarily for internal ceilings where weight is a concern and impact resistance is not required.

2. Medium Density (1.0 – 1.2 g/cm³): Common for general partitioning and backer boards.

3. High Density (> 1.3 g/cm³): The standard for exterior cladding, flooring, and high-impact areas. TSM focuses on high density fiber cement board (≥1.4 g/cm³) because density drives three critical engineering advantages:

First is Hydrophobicity. In a high-density board, the particles are compressed so tightly that there are fewer microscopic voids for water to enter. This significantly lowers the water absorption rate, which is the primary defense against frost damage. Water expanding into ice within a porous board is the leading cause of facade failure.

Second is Modulus of Rupture (MOR). High density correlates directly with bending strength. A TSM board can withstand significant wind loads and physical impacts without fracturing.

Third is Acoustic Performance. Mass blocks sound. The sheer fiber cement board weight contributes to significant acoustic dampening. Using high-density boards in partition walls can improve the Sound Transmission Class (STC) rating by several decibels compared to standard drywall.

Critical Applications: Where Engineering Meets Design

The versatility of fiber cement allows it to serve multiple roles in a construction project.

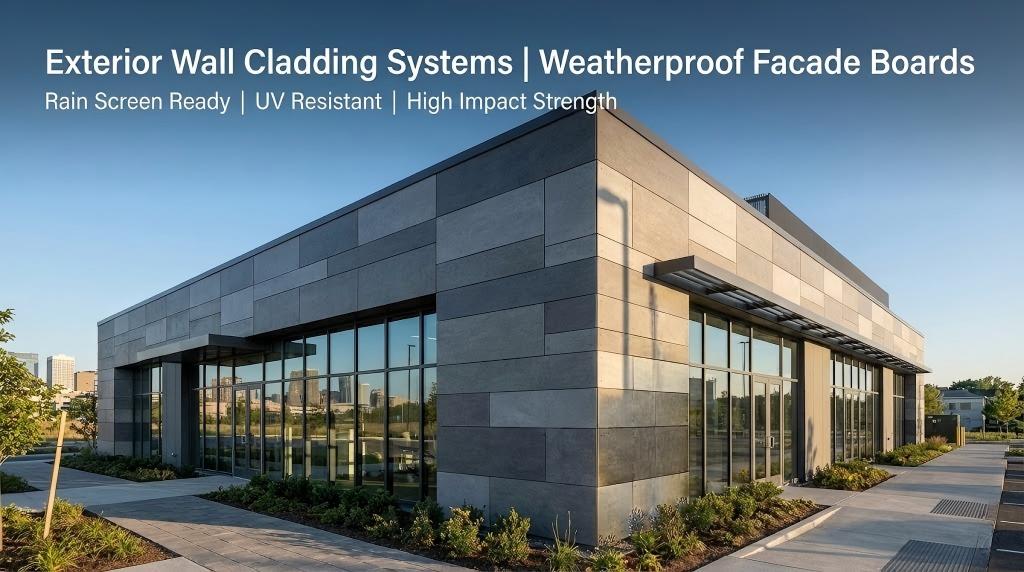

Exterior Facades and Cladding

As a rainscreen cladding material, fiber cement offers the aesthetic of stone or wood without the maintenance. It withstands UV radiation without degrading. Unlike vinyl, it does not become brittle in the cold or melt in heat. It is a ‘fit and forget’ solution for building envelopes.

Flooring Substrates

In flooring, rigidity is key. Tile floors crack when the subfloor deflects (bends) under load. Plywood is flexible and susceptible to moisture rot. 18mm or 20mm high-density fiber cement boards provide a rock-solid, moisture-proof deck for tiling, especially in wet areas like bathrooms or kitchens.

Fire Protection

With a Class A1 non-combustible rating, these boards are essential for passive fire protection. They are used to line elevator shafts, create firewalls in commercial spaces, and protect steel structures from heat deformation during a blaze.

The Spec Lab: TSM vs. Standard Boards

Data provides clarity. The table below highlights the performance gap between generic cement boards and TSM’s engineered solutions.

| Parameter | Standard Cement Board | TSM Fiber Cement Board |

| Density | 1.0 – 1.2 g/cm³ | ≥ 1.4 g/cm³ (High Density) |

| Composition | Cement + Mesh | Cement + Quartz + Cellulose |

| Fire Rating | Class A | Class A1 (Non-Combustible) |

| Moisture Movement | > 0.10% | < 0.04% (Autoclaved Stability) |

| Asbestos Content | Risk in unregulated boards | 0% (100% Non-Asbestos) |

| Durability | 10-15 Years | 50+ Years |

| Freeze-Thaw | Prone to cracking | Tested for 100+ Cycles |

The ‘Moisture Movement’ metric is particularly telling. A movement of less than 0.04% means that for every meter of board, expansion is negligible, preventing the common issue of joint cracks.

Installation Best Practices: Avoiding Failure

Even the best material can fail if installed incorrectly. Successful installation relies on managing the board’s hardness and movement.

Cutting

Due to the high silica content, cutting requires diamond-tipped blades. For thinner boards (<8mm), a score-and-snap method works, but for structural boards (18mm+), power tools with dust extraction are necessary to ensure clean edges and safety.

Fastening

Never nail high-density fiber cement near the edge; it may spall. Self-drilling screws with countersinking heads are recommended. Screws should be placed at least 15mm from the edge and 50mm from corners.

Gapping

Although TSM boards are stable, the building structure itself moves. Always leave a 3-5mm expansion gap between boards, filled with a flexible polyurethane sealant or finished with a specialized jointing compound.

Buying Direct: The Strategic Advantage

For large-scale construction projects, the supply chain is as critical as the material itself. Sourcing through intermediaries often dilutes technical accountability.

Working directly with a dedicated manufacturing facility allows for greater control. It offers customization in dimensions (e.g., cutting to specific ceiling tile sizes to reduce waste) and ensures rigorous quality assurance. For architects, access to TSM Board technical data regarding screw spacing and framing logic is invaluable.

FAQ: Technical Inquiries

Q: Is fiber cement board waterproof?

A: It is water-resistant, meaning it is not structurally damaged by water. It will not rot, swell significantly, or lose strength when wet. However, it is breathable (vapor permeable). For wet areas like showers, it acts as the perfect stable substrate for waterproofing membranes, but the board itself should not be used as the primary water barrier.

Q: Can I paint fiber cement board?

A: Yes, it is an excellent substrate for paint. Because it does not contain the oils found in wood, paint adheres exceptionally well and lasts longer. We recommend using 100% acrylic latex paints. Ensure the board is clean and dry before application.

Q: How does it compare to Magnesium Oxide (MgO) board?

A: While MgO boards are also fireproof, they have faced issues with chloride leaching (the ‘crying board’ phenomenon) which can corrode steel fasteners. Fiber cement is chemically stable and does not corrode metal, making it a safer long-term investment for structural steel buildings.

Q: What is the lifespan of fiber cement?

A: When installed correctly, fiber cement has a lifespan exceeding 50 years. It is resistant to termites, rot, UV, and fire, meaning it often outlasts the building’s lifespan.

Conclusion: The Gold Standard

The evolution of construction materials is consistently moving towards durability, safety, and sustainability. Fiber cement board represents the maturity of this evolution. It eliminates the rot of wood, the fragility of gypsum, and the heavy weight of masonry, offering a solution that is engineered for the future.

For architects and contractors, choosing TSM means choosing predictability. It is a material that behaves consistently in inconsistent environments. To discuss specifications for your next project, contact TSM Factory directly.

Unlike traditional masonry, which can be heavy and brittle, or gypsum, which is susceptible to moisture, fiber cement is a sophisticated composite material. It represents a synthesis of three primary components: Portland cement (the binder), high-purity silica sand (the aggregate), and reinforcing fibers. When combined under precise industrial conditions, these elements transform into a calcium silicate structure that outperforms its individual components in almost every metric.

However, not all boards are created equal. The market is flooded with variations in density, curing processes, and fiber quality. This guide moves beyond surface-level marketing to analyze the technical reality of fiber reinforced cement board. We will dissect the history of the Hatschek process, the molecular impact of autoclaving, the critical importance of density, and why this material has become the global standard for heavy-duty cladding and flooring applications.