The global construction industry is facing a crisis of efficiency. Traditional wet construction methods—bricklaying, mortar mixing, and plastering—are labor-intensive, slow, and heavily dependent on skilled craftsmanship. In an era of labor shortages and tight project timelines, the industry is pivoting toward Modular and Prefabricated solutions. Leading this revolution is the EPS cement sandwich panel.

This is not merely a material; it is a complete wall system. By fusing the structural rigidity of fiber cement with the thermal insulation of expanded polystyrene (EPS), engineers have created a composite that is lighter than blockwork, stronger than drywall, and faster to install than both.

This guide provides a comprehensive technical breakdown of TSM’s Prefab Solutions. We will dissect the anatomy of the panel, analyze its load-bearing capabilities for hanging heavy appliances, and calculate the thermal advantages that make it the premier choice for modern eco-buildings.

Anatomy of a Panel: The Composite Advantage

To understand the performance, we must look at the cross-section. An EPS sandwich panel is a three-part composite structure designed to optimize the strength-to-weight ratio.

1. The Exoskeleton (Face Sheets): The outer layers consist of 5mm high-density Calcium Silicate Boards. These provide the impact resistance, fire protection, and a smooth surface ready for painting. They act like the flanges of an I-beam, resisting bending moments.

2. The Matrix (Core): The center is a mixture of Portland cement, EPS (Expanded Polystyrene) beads, and fine sand. This core is not just filler; it is a structural composite cement board matrix that binds the two face sheets together, preventing buckling.impact resistant board. In standard sandbag drop tests (30kg sandbag dropped from a height), the panel shows zero through-cracks. The EPS beads acts as microscopic shock absorbers, dissipating kinetic energy.

This synergy creates a ‘Solid Wall’ feel. Unlike hollow drywall partitions which sound drum-like when knocked, an EPS panel sounds and feels solid, providing the perceived quality of masonry without the weight.

Lightweight Physics: Impact & Load

A standard 100mm thick brick wall weighs approximately 180kg/m². A 100mm TSM EPS Panel weighs just 65kg/m². This 60%+ reduction in dead load allows structural engineers to reduce the size of columns and foundations, saving massive amounts of concrete and steel in the building’s skeleton.

But is it weak? No. It is an

The Hanging Strength Test

The most common question from contractors is: ‘Can I hang a TV on it?’

• Drywall: Requires finding a stud or using toggle bolts (Max load ~15kg).

• EPS Panel: Because it has a solid cementitious core, you can use a standard expansion bolt anywhere on the panel face. The single-point hanging strength exceeds 50kg, making it safe for heavy AC units, water heaters, and marble cladding.

Construction Efficiency: The “Man-Hour” Calculation

Time is the most expensive commodity on a job site. As a superior alternative to gypsum board partitions, EPS panels drastically shorten the critical path.

• Brick Wall Speed: A skilled mason lays ~10m² per day. Then it needs 7 days to cure. Then plastering. Then drying. Total time: 14 days.

• EPS Panel Speed: Two workers can install ~40m² per day. No plastering required (just joint taping). Ready for paint immediately. Total time: 1 day.

For a 20-story hotel project, switching to TSM EPS panels can reduce the construction schedule by 3-4 months, significantly lowering financing costs.

Thermal & Fire Physics: The Best of Both Worlds

Usually, materials are either good insulators (foam) but flammable, or fireproof (concrete) but poor insulators. The EPS Cement Sandwich Panel bridges this gap.

Thermal Insulation (R-Value)

The EPS beads trapped in the core trap air, significantly reducing thermal conductivity. A 75mm EPS panel offers equivalent thermal insulation to a 240mm brick wall. This built-in efficiency lowers the HVAC load of the building.

Fire Resistance

Crucially, TSM panels are classified as fire resistant building materials. The face boards are Class A1 Non-Combustible. The core is protected by the cement matrix. A 100mm panel achieves a fire rating of 4 hours (240 minutes), far exceeding the requirements for residential or commercial partition walls.

System Comparison: EPS vs. Traditional

| Feature | TSM EPS Panel | Brick / Block | Drywall (Gypsum) |

| Installation Speed | Very Fast (40m²/day) | Slow (10m²/day) | Fast (30m²/day) |

| Weight (Dead Load) | Light (65kg/m²) | Heavy (180kg/m²) | Light (30kg/m²) |

| Solid Feel | Solid (Masonry feel) | Solid | Hollow (Drum sound) |

| Hanging Load | High (>50kg) | High | Low (<15kg) |

| Moisture Proof | Yes (Waterproof face) | No (Absorbs) | No (Rots) |

| Wiring | Conduit channels needed | Chasing needed | Easy (Cavity) |

Installation SOP: Tongue & Groove Assembly

The secret to the panel’s stability is the connection. Review our EPS Sandwich Panels technical manual for full details, but here is the core logic:

1. Alignment: Install U-channel tracks on the floor and ceiling.

2. Adhesive: Apply polymer cement mortar to the Tongue and roove (T&G) edges of the panel.

3. Connection: Slide the panel into place. Using a crowbar, force the panels tightly together so mortar squeezes out of the joint.

4. Reinforcement: Hammer steel rebar pins at a 45-degree angle through the joint to mechanically lock the panels together.

5. Wiring: For electrical conduits, use a portable cutter to chase a groove in the panel, insert the pipe, and fill with mortar. The cement core holds the fill perfectly.

FAQ: Prefab Construction

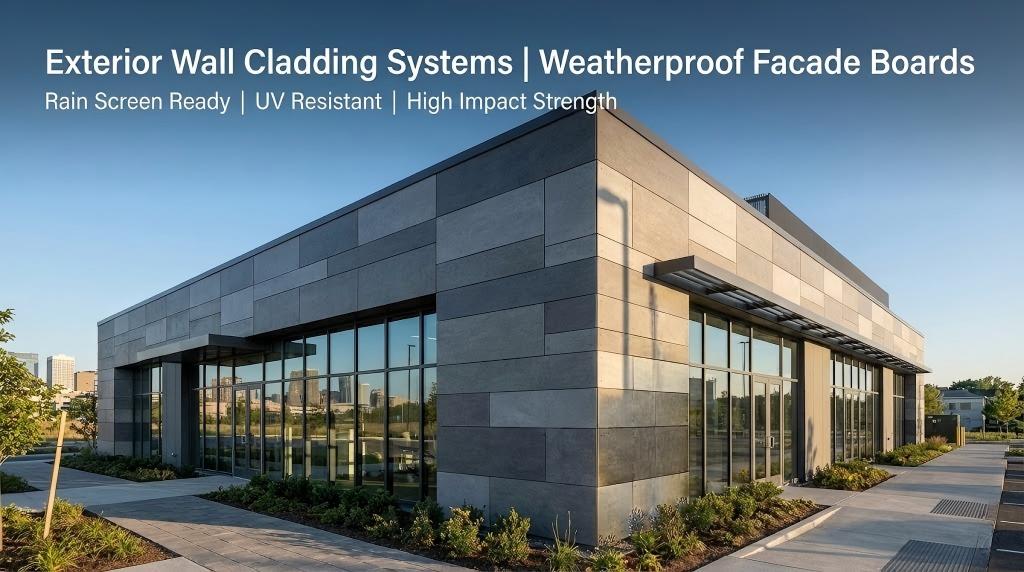

Q: Can I use it for exterior walls?

A: Yes. For exterior use, we recommend 125mm or 150mm thickness for enhanced insulation. It must be coated with an exterior paint or cladding system to protect the joints from weather.

Q: How soundproof is it?

A: A 100mm panel has an STC (Sound Transmission Class) of approximately 44-46dB, which is superior to a standard 4-inch brick wall. It is suitable for hotel separation walls.

Q: Can it be cut on site?

A: Yes, standard circular saws with diamond or tungsten blades cut through it easily. It produces dust, so masks are mandatory.

Conclusion: Building Smarter, Not Harder

The EPS Cement Sandwich Panel is more than a product; it is a strategy. It solves the trifecta of construction challenges: Speed, Cost, and Quality.

For developers looking to maximize ROI by reducing project timelines, TSM offers the ultimate solution. Contact our team to discuss how our Prefab Solutions can be integrated into your next high-rise or villa project.