The building envelope is the most complex component of modern architecture. It acts as the primary filter between the controlled interior environment and the chaotic exterior climate. It must withstand UV radiation, driving rain, freeze-thaw cycles, and wind loads, all while allowing the building to ‘breathe’ and release trapped internal moisture. This delicate balance is the domain of the exterior wall cladding system.

Historically, buildings relied on mass walls (thick stone or brick) to absorb and dissipate moisture. However, modern construction favors lightweight, insulated frames protected by a rainscreen skin. In this context, the choice of cladding material is critical. Architects are increasingly moving away from reactive materials like vinyl (which warps) or wood (which rots) toward stable, engineered solutions.

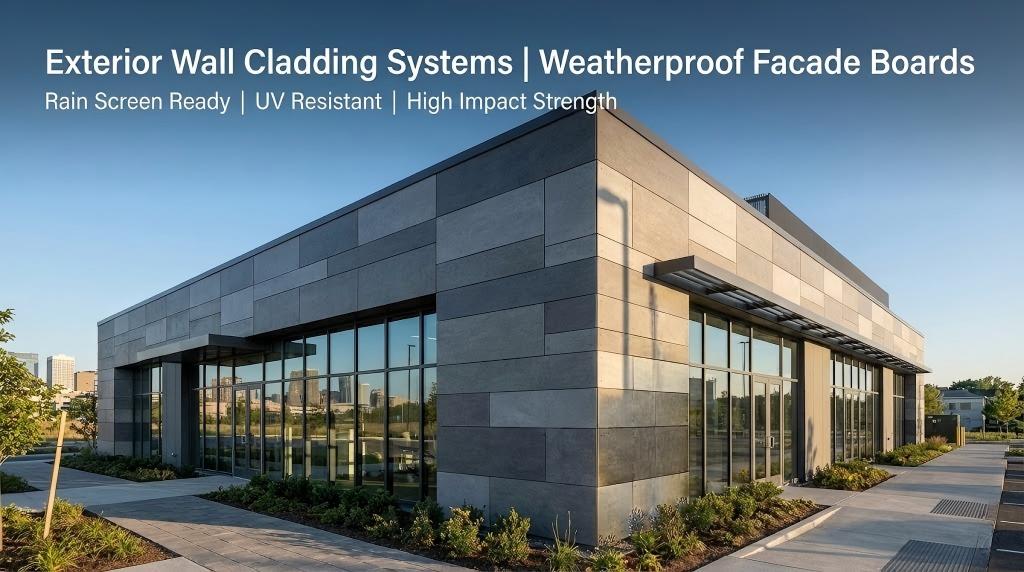

Among these, high-density fiber cement wall board has emerged as the global standard for high-performance facades. This guide offers a deep technical dive into why fiber cement is the superior choice for commercial and residential exteriors, analyzing its physics, fire safety, and lifecycle economics.

The Physics of Weathering: Thermal Expansion

One of the primary causes of facade failure is not rain, but temperature. Every material on earth changes its dimensions when heated or cooled. This phenomenon is quantified by the Coefficient of Thermal Expansion (CTE).

The Vinyl Failure Mode

PVC (Vinyl) siding has a very high CTE. In the height of summer, a long run of vinyl siding can expand by several centimeters. If the installer has nailed it too tightly, the material has nowhere to go and will buckle outwards, creating a wavy appearance known as ‘oil canning.’ Conversely, in freezing winter temperatures, the plastic contracts and becomes brittle. A simple impact from a hailstone or a stray baseball can shatter the siding.

The Fiber Cement Solution

TSM boards are composed of silica sand and cement, mineral materials with an extremely low CTE. They are dimensionally inert. A TSM board installs flat and stays flat, regardless of whether it is -20°C or +40°C. This stability is the defining characteristic of true weather resistant building materials. It ensures that the caulk joints do not stretch to the point of failure, maintaining the airtight integrity of the building envelope for decades.

The Rainscreen Principle: Managing Moisture

The most advanced application of fiber cement is in a ‘Ventilated Rainscreen’ system. This design philosophy accepts that water will eventually bypass the outer defense, and manages it through physics rather than relying on a perfect seal.

1. The Deflection Layer: The fiber cement board acts as the first line of defense, deflecting 90% of rain and solar energy.

2. The Drainage Plane: Any water that penetrates joints enters a cavity behind the board. Gravity drains this water down to a flashing outlet.

3. The Drying Zone: This is the most critical aspect. The cavity allows for continuous airflow. As the sun heats the facade, the air in the gap rises (Stack Effect), pulling in cool, dry air from the bottom. This constant ventilation evaporates any residual moisture on the structural wall or insulation.

For a rainscreen to function, the outer skin must be rigid and waterproof. TSM fiber cement siding is ideal because it is inorganic. Even if the cavity environment remains damp for extended periods, the board will not feed mold or rot, unlike wood furring strips or plywood sheathing.

Fire Safety: The A1 Standard

In the wake of high-profile facade fires (like Grenfell Tower), fire safety is the single most important specification for mid-to-high rise buildings. Many composite panels (ACP) contain polyethylene cores that melt and fuel the fire, acting like a vertical river of gasoline.

TSM Fiber Cement is rated EN 13501-1 Class A1. This stands for ‘Non-Combustible.’ It does not burn, it does not melt, and it does not release toxic black smoke. Installing an A1 rated impact resistant board effectively creates a fire shield around the building. In the event of an external fire source, the cladding will not propagate the flame to upper stories, buying critical time for evacuation.

Mechanical Durability: Impact Resistance

Facades at ground level face different threats: physical abuse. Schools, hospitals, and public transport hubs are high-traffic zones where walls are frequently struck by maintenance carts, balls, or vandalism.

Standard stucco cracks upon impact. Aluminum dents. Fiber cement, particularly high-density variants (>1.5 g/cm³), utilizes a tight crystalline matrix reinforced with cellulose fibers. This structure dissipates kinetic energy. It can withstand significant point loads without fracturing, reducing the maintenance budget significantly over the building’s life.

Design Versatility: Wood Aesthetics without the Rot

Architects love the warmth of wood, but building owners hate the maintenance. Natural cedar siding requires staining every 3-5 years and is prone to woodpecker damage and termites.

TSM offers the perfect compromise: deep-embossed rainscreen cladding system boards that mimic the texture of natural timber. Because the wood grain is impressed into the cement during the autoclaving process, it is permanent. When painted, it is indistinguishable from wood from a distance of two feet, yet it offers the durability of stone.

The Economics: Lifecycle Cost Analysis (LCA)

When choosing cladding, one must look beyond the initial purchase price to the Total Cost of Ownership (TCO) over 50 years.

• Vinyl: Low initial cost, but low property value and short lifespan (20 years). Replaced twice in 50 years.

• Wood: Medium initial cost, but extremely high maintenance (painting/sealing). High TCO.

• Fiber Cement: Medium initial cost, low maintenance (paint lasts 15+ years), extreme longevity (50+ years). Lowest TCO.

Material Performance Matrix

| Material | Fire Class | UV Stability | Maintenance Cycle |

| TSM Fiber Cement | A1 (Non-Combustible) | Inert (Excellent) | Paint every 15-20 yrs |

| Vinyl (PVC) | Melts / Toxic Smoke | Fades / Brittle | None (Replace in 20 yrs) |

| Natural Wood | Combustible | Poor (Greys/Rots) | Stain every 3-5 yrs |

| Stucco | Non-Combustible | Good | Repair cracks every 10 yrs |

FAQ: Exterior Specifications

Q: Can I paint exterior cement cladding?

A: Yes. Unlike vinyl, fiber cement is an absorbent substrate that bonds chemically with acrylic latex paints. This bond is so strong that paint on fiber cement typically lasts 2-3 times longer than on wood. TSM also offers factory-primed or pre-finished options.

Q: How do you hide the joints?

A: There are two schools of thought. For a seamless ‘stucco’ look, joints can be recessed and filled with a specialized epoxy compound. However, modern architecture often celebrates the joint. We recommend a ‘shadow gap’ or open-joint rainscreen installation, which adds depth and texture to the facade while simplifying installation.

Q: Is it heavy? Does it require special framing?

A: High-density board is heavier than vinyl but lighter than real stone or brick. Standard timber or light-gauge steel framing at 600mm centers is sufficient to support the load. No reinforced foundation is required, unlike full masonry walls.

Conclusion: The Permanent Facade

A facade is the face of a building. It defines the first impression and protects the asset value. Choosing a cheap material means committing to a cycle of degradation and repair. Choosing fiber cement means building for the next generation.

It is the intersection of aesthetics and armor. Ready to upgrade your exterior? View Exterior Projects to see the transformation, or Request Siding Samples to feel the density yourself.